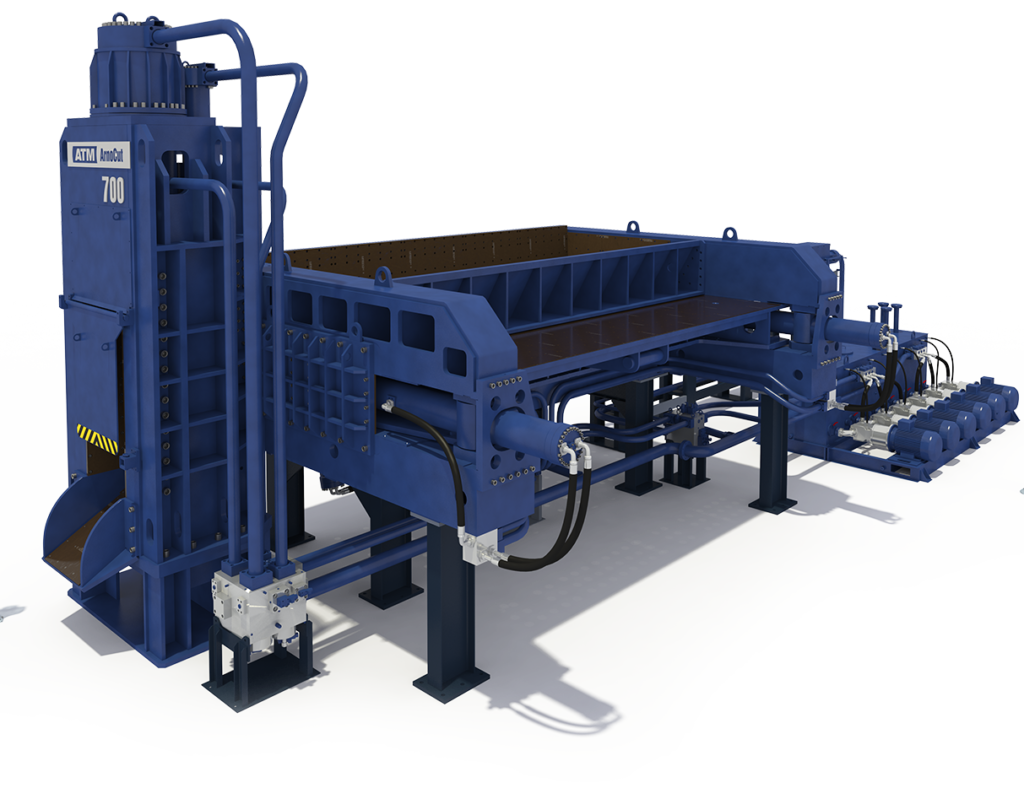

Arno®Cut

Arno®Cut Series Scrap Shears are the best choice for pre-compacting and cutting of metal plates and components, car body parts and similar light- to medium weight scrap.

Even steel rails can be cut with special notch blades. The machines are available in six sizes from 4,000 to 13,000 kN shear force. All compacting chamber wear plates are made of Hardox 400 up to Hardox 500 and guarantee highest quality and a long service life.

Cutting cycles are optimised by linear transducer systems in the cylinders. The need for an elaborate foundation is avoided thanks to the monobloc construction. A centralized lubrication system, various clogging indicators and fault analysis guarantee simple maintenance. Comfortable operation with two joysticks and a multifunctional display in a soundproof, airconditioned cab make the scrap shear a workplace with the highest level of safety and productivity.

| Technical Data Arno®Cut | 400 | 600 | 700 | 850 | 1000 | 1300 | |

|---|---|---|---|---|---|---|---|

| Cutting force | kN | 4000 | 6000 | 7000 | 8500 | 10000 | 13000 |

| Downholder force | kN | 1850 | 1850 | 1850 | 2500 | 3050 | 3200 |

| Lid force | kN | 2000 | 2000 | 2000 | 2000 | 2800 | 2800 |

| Side force | kN | 2500 | 2500 | 2800 | 2800 | 3600 | 3600 |

| Feed force | kN | 1500 | 1500 | 1000 | 1000 | 1200 | 1200 |

| Cutting width | mm | 420 | 640 | <800 | <1000 | <1000 | <1200 |

| Filling height | mm | 520 | 600 | 600 | 700 | 800 | 1000 |

| Filling length | m | <4,1 | <6,5 | <6 | <6 | <6 | <6 |

| Capacity | t/h | <10 | <15 | <20 | <30 | <40 | <50 |

| Cuts per minute | pro min | <5 | <6 | <6 | <6 | <6 | <6 |

| Power standard | kW | 110 | 220 | 270 | 330 | 440 | 550 |

| Installation surface | m x m | 6 x 15 | 6 x 18 | 7 x 18 | 7 x 20 | 7 x 22 | 9 x 24 |